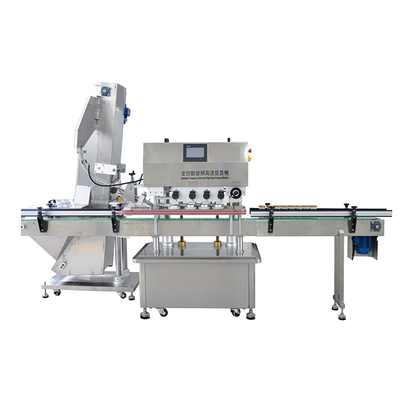

Shampoo Full Automatic Filling Machine , AC220V Liquid Detergent Filling Machine

Product Details:

| Place of Origin: | Guangdong, China |

Payment & Shipping Terms:

| Price: | $44,000.00 - $50,000.00/units |

|---|---|

| Packaging Details: | standard export wooden case |

| Supply Ability: | 20 Unit/Units per Month |

|

Detail Information |

|||

| Machinery Capacity: | 400BPH, 2000BPH, 1000BPH, 1500BPH, 1800BPH | Applicable Industries: | Hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use |

|---|---|---|---|

| Application: | Food, Beverage, Commodity, Chemical, Machinery & Hardware | Packaging Type: | CANS, Bottles |

| Packaging Material: | Plastic, Glass | Driven Type: | Electric |

| Voltage: | AC220V | Dimension(L*W*H): | 2000x1600x1900mm |

| Weight: | 600 KG | Key Selling Points: | High-accuracy |

| Filling Material: | Milk, Water, Oil, Juice | Filling Accuracy: | 1%, ±1mm |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 2 Years | Core Components: | Motor, Pump, Other, PLC, Gear, Gearbox, Engine |

| Product Name: | Automatic Filling And Capping Machine | Applicable Bottle Diameter: | 20~50 Mm |

| Applicable Bottle Height: | 30~100 Mm | Filling Speed: | 1000~2000 Pcs/hour |

| Filling Volume: | 5-60ml | Control: | PLC+ Touch Screen |

| Air Consumption:: | PLC+ Touch Screen | Bottle Material: | Glass Bottle, Plastic Bottle |

| Advantage: | Automatic Working | ||

| Highlight: | AC220V Full Automatic Filling Machine,PLC Liquid Detergent Filling Machine,60ml Filling Production Line |

||

Product Description

Full Automatic Filling Machine Liquid Detergent Filling Machine Shampoo Filling Production Line

Specification

|

Product name |

Automatic Filling And Capping Machine |

|

Applicable bottle diameter |

20~50 mm |

|

Applicable bottle height |

30~100 mm |

|

Filling speed |

1000~2000 pcs/hour |

|

Filling volume |

5-60ml |

|

Control |

PLC+ Touch Screen |

|

Air consumption: |

PLC+ Touch Screen |

|

Bottle material |

Glass bottle, plastic bottle |

|

Advantage |

Automatic Working |

|

Feature |

High Efficiency |

Machine Equipment:

1. 304 stainless steel machine framing

2. ”Yudian” PID temperature controller 48*48

3. Servo motor controlled the bag moving

4. Vacuum pump to provide vacuum for pouch pickup and opening, reliable, lower noise and less maintenance.

5.“Panasonic” PLC and “Kinco” control system to control whole machine (as standard).

6. Include one timing hoper for one bag width (Size to be confirmed)

7. English touch screen display

![]()

![]()